We’re trying something new this spring: we’re sugarin’ our maple trees!

We’re trying something new this spring: we’re sugarin’ our maple trees!

It’s fun to see how things are made, and in my opinion the best way to see is to do.

The process began a while ago, when we talked about doing it. We live on a small, quarter-acre lot in a somewhat urban-ish setting. It’s entirely possible that our tiny plot of land has the most trees of any other parcel on our block. (Or several blocks.) Appropriately enough for the task of making our own maple syrup, many of them are maples!

After initially assessing the plausibility of our task, we decided to do it! Part of my encouragement towards this particular backyard project comes from college friends of ours (one of whom I work closely with on many web projects) who have been “sugarin'” for years. (They strangely took a break this particular winter… the first winter we are giving it a go…) A couple seasons ago they sent us a sample of their work; it was delicious!

We knew that we would need to put taps/spouts in our trees—later we would learn that they are called spiles—and some containers to collect the sap, and then finally some way of cooking down the sap.

And that’s about what we knew.

Thankfully, the friends mentioned above recently used an episode of their weekly podcast to explain in great detail the wonders (and the challenges) of maple sugaring. (You can listen to it here.) They also recommended a few good resources, including a book called Backyard Sugarin’, which I promptly placed on hold at our local library. All of that came together nicely to help build my confidence towards giving this a try.

And so, on one chilly, late-winter afternoon… I bought six spiles.

It’s a meager, humble beginning; but it’s a beginning.

(A two week adventure through hockey tournaments, three separate family birthdays, and LOTS of really hefty sickness delayed the implementing of this project. That, however, is for a different post. Or… perhaps none at all.)

Early this morning, just after the sun fully brightened the March sky, I decided to tap my maple trees. The book had suggested using empty plastic milk containers to collect the sap (rather than the more expensive option of tin buckets with cool lids) and since we are always happy to find an equal-but-less-costly option, I gladly rummaged through our recycling bin. To my chagrin, there were only a couple containers that did not have that lovely milk-not-quite-completely-rinsed-out aroma, so I emptied the 1/3 of a gallon (or so) of milk in the open container in our fridge into a different container, and was thus able to score two sap collection containers to get us started.

Our property is quite long. It’s a walk of a couple hundred feet from the road to the back property line. The healthiest maple tree on the premises is about five short feet from the back of this long plot of dirt. Now, I say all of this because I was going to need to drill holes. And my only drill is not cordless.

So I needed extension cord. And plenty of it!

I unburied and unwound both hundred-foot, bright orange extension cords sitting in our basement and—sap collectors, spiles, hammer and drill in hands—I headed straight for the nearest maple!

It was mighty chilly this morning still, and with only two containers, and having no idea if this would even work, I decided to stick to the two maples closest to our house. (Half of that extension cord for now naught. At least, temporarily.) I plugged in my drill, tightened the bit, and looked for a good spot to drill.

It was mighty chilly this morning still, and with only two containers, and having no idea if this would even work, I decided to stick to the two maples closest to our house. (Half of that extension cord for now naught. At least, temporarily.) I plugged in my drill, tightened the bit, and looked for a good spot to drill.

I knew that it was good to drill on the south or southwest side, as that would receive the most sun. Sun gets the sap flowing. I also knew that sap flows best toward a large root. Figuring that our giant maple would be a good candidate for more than one tap (eventually) I chose that tree first, and found a good south-side, root-below spot to drill my hole.

It felt pretty weird to take a drill to my living tree, I’ll have you know…

I drilled at a slight upward angle, and out came the fresh tree shavings. My bit actually got stuck and came out of the drill! I wiggled it free and made sure to keep the drill speed up a bit higher, and was able to make the appropriate 1 1/2″-deep hole. No sap was flowing early in the morning, so I took my time and gently tapped in the perfectly-fitting spile. It all seemed to be going great! (Aside from the no sap, part…) I hooked the first milk container onto the spile, and headed toward the second maple.

Having gained some confidence from the first tap, I quickly found the perfect spot, drilled (more successfully this time) and hung the second sap collection unit. (A better sounding name, don’t you think?)

I had no idea if this was going to work. Really. I quietly collected my tools and put everything back where it belongs, and went on with my day. There was still more sick care to be given to many members of the family. There was a good deal more parenting to do as the Mom is one of the sicker family members at the moment. There was work to be done as well. A normal, full day of life.

As the day was coming to a close, I remembered the taps.

About 4:30pm or so, I checked on the second tap, which is near the front of our property, visible from our front porch.

About 4:30pm or so, I checked on the second tap, which is near the front of our property, visible from our front porch.

IT WAS FULL!!!

OK, not full… but it held enough clear liquid for me to use ALL CAPS to relay to you the excitement I felt when my eyes first beheld that sight!

I ran inside to get shoes on and to get as many kids as could amble to see the start of this latest backyard adventure! They quickly finished up a task I requested that they complete, shoed and coated up, and we headed out our front door, camera in hand!

There were gasps of excitement, joyful, exuberant jumping, clapping, and lots of rapid-fire questions. I snapped some photos, and explained the whole process I had gone through early that morning, and we decided to do one more tap following our apparent success!

Kirsten was perhaps the most excited of all four kiddos. (Cam joined us later, unwilling to miss the backyard project party, though he was not conscious for much of today thanks to his current battle with sickness…) Kirstie wore the biggest smile, asked the most questions, and hung on every word of my stories and instruction.

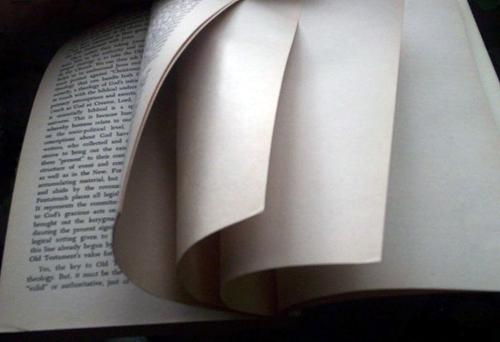

Following a very successful third tap—we decided to tap the healthiest maple, the one at the back of our property, and the sap was flowing within a second of the drill first penetrating the tree!—Kirsten discovered the book I had gotten from the library, and began flipping through the pages, yearning to learn more. I saw this and said, “Kirstie, you can read that if you’d like. That’d be great.” At this, she quickly headed for the living room couch, a visible bounce in her gait!

Following a very successful third tap—we decided to tap the healthiest maple, the one at the back of our property, and the sap was flowing within a second of the drill first penetrating the tree!—Kirsten discovered the book I had gotten from the library, and began flipping through the pages, yearning to learn more. I saw this and said, “Kirstie, you can read that if you’d like. That’d be great.” At this, she quickly headed for the living room couch, a visible bounce in her gait!

Learning is fun. Doing is also fun. Combined, they are really fun! And learning by doing together… you can’t beat it.

Now hopefully we’ll get the boiling down the sap part right, and have a super-tasty final product!

But even if we don’t… I can unabashedly say this backyard project has already been a wonderful success!

It’s almost time to start tapping our maple trees! March is just around the figurative corner. The days are getting a bit longer, the weather a bit warmer—right? It is, isn’t it?—and with all of that comes maple sugaring season!

It’s almost time to start tapping our maple trees! March is just around the figurative corner. The days are getting a bit longer, the weather a bit warmer—right? It is, isn’t it?—and with all of that comes maple sugaring season!

We’re trying something new this spring: we’re sugarin’ our maple trees!

We’re trying something new this spring: we’re sugarin’ our maple trees!

It was mighty chilly this morning still, and with only two containers, and having no idea if this would even work, I decided to stick to the two maples closest to our house. (Half of that extension cord for now naught. At least, temporarily.) I plugged in my drill, tightened the bit, and looked for a good spot to drill.

It was mighty chilly this morning still, and with only two containers, and having no idea if this would even work, I decided to stick to the two maples closest to our house. (Half of that extension cord for now naught. At least, temporarily.) I plugged in my drill, tightened the bit, and looked for a good spot to drill. Following a very successful third tap—we decided to tap the healthiest maple, the one at the back of our property, and the sap was flowing within a second of the drill first penetrating the tree!—Kirsten discovered the book I had gotten from the library, and began flipping through the pages, yearning to learn more. I saw this and said, “Kirstie, you can read that if you’d like. That’d be great.” At this, she quickly headed for the living room couch, a visible bounce in her gait!

Following a very successful third tap—we decided to tap the healthiest maple, the one at the back of our property, and the sap was flowing within a second of the drill first penetrating the tree!—Kirsten discovered the book I had gotten from the library, and began flipping through the pages, yearning to learn more. I saw this and said, “Kirstie, you can read that if you’d like. That’d be great.” At this, she quickly headed for the living room couch, a visible bounce in her gait! It was the best of times, it was the worst of times…

It was the best of times, it was the worst of times…

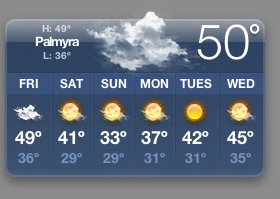

Check out the forecast: 50º right now, and not a freezing temp in sight!

Check out the forecast: 50º right now, and not a freezing temp in sight!

Before the water, though, we had to paint!

Before the water, though, we had to paint! We determined the amount of wood needed. Even divided it up in the 2 x 8, 2 x 10, and 2 x 12s, according to where they would be placed in relation to the grade of the land. (Which, is probably a tad too steep for an ice rink!) We had it all nicely planned out, and even laid out.

We determined the amount of wood needed. Even divided it up in the 2 x 8, 2 x 10, and 2 x 12s, according to where they would be placed in relation to the grade of the land. (Which, is probably a tad too steep for an ice rink!) We had it all nicely planned out, and even laid out. Once we had cut all the boards, we had to fit them all together. Sadly, we did not measure the length of the angled boards very meticulously. What we did was just push the boards out as far as the angled boards “forced” us to go. (This will come into play just a bit later in the story. Stay tuned.) Once we had made our oval based upon that, we discovered that we had about an 8-to-10″ gap left! HA! NOT what we were expecting, but we knew we could fix it later.

Once we had cut all the boards, we had to fit them all together. Sadly, we did not measure the length of the angled boards very meticulously. What we did was just push the boards out as far as the angled boards “forced” us to go. (This will come into play just a bit later in the story. Stay tuned.) Once we had made our oval based upon that, we discovered that we had about an 8-to-10″ gap left! HA! NOT what we were expecting, but we knew we could fix it later. We cut the board, placed it, and hammered in the remaining stakes. Now it was time to lay out the plastic liner! Whoohoo!

We cut the board, placed it, and hammered in the remaining stakes. Now it was time to lay out the plastic liner! Whoohoo!